The city of Würzburg was awarded the contract for the construction of a new business incubator as part of the „Digital Founder Centres“ support programme of the Bavarian State Ministry of Economic Affairs and Media, Energy, and Technology on the basis of the concept presented there.

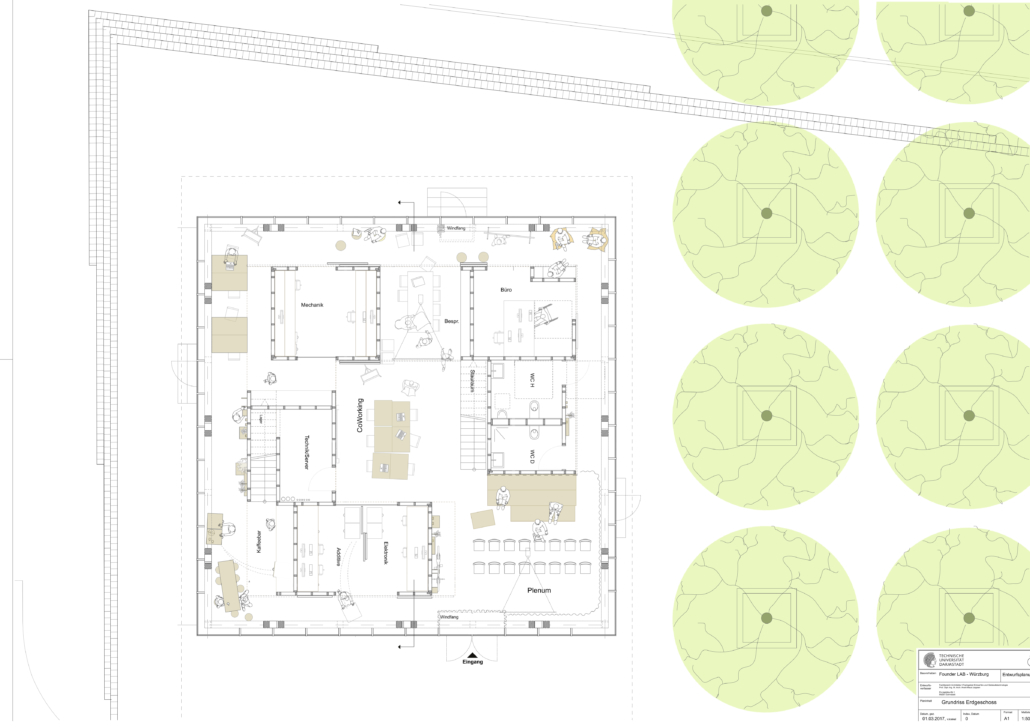

Together with the city of Würzburg as the client, the Centre for Digital Innovations (ZDI) Mainfranken as the user and the Department of Design and Building Technology of the TU Darmstadt headed by Prof. Anett-Maud Joppien as it ́s design author and planner; the innovative model project FounderLAB is being developed based on the preliminary work from the projects CUBITY and LivingLAB.

The FounderLAB will be built on a central, slightly elevated quarter square of the Landesgartenschau 2018, on the conversation area of the former Leighton Baracks. The foundation stone will be laid on 28 June 2017 and will be inaugurated by Franz Josef Pschierer, Minister of State for Economics, Energy and Technology, on 9 May 2018. henne schönau architekten were responsible for the planning submission, working + tender documents, and site supervision.

Today, the FounderLAB site is embedded in a central park and belongs to the new Hubland district which is currently under construction. The Hubland campus of the Julius-Maximilians-University of Würzburg, in the immediate vicinity are housing and shopping/ supply facilities. Thus young founders will find optimal living and working conditions as well as recreational opportunities in the vicinity of the business incubator.